Advanced Intelligent Systems Inc.

Intelligent Data-Driven Cloud-Based Management Platform To Improve Processes and Products

Convenience and Control

AIS Connect brings visibility, control, and ease of management to machines in the agricultural industry. This saves businesses time and money while increasing quality & output.

AIS started with a Robot as a Service (RaaS) business model. AIS Connect allows AIS to extend its services to machine manufacturers and enable them to offer their products to nurseries with a Machinery as a Service (MaaS) business model. Data collected by AIS Connect is employed both for day-to-day operations and as a source for big data analytics and process improvement. Part of the data exchanged on AIS Connect is the amount of work performed by the machines and invoices issued by the machine providers. AIS Connect also includes a system for after-sales support and issue tracking.

The AIS Connect Advantage

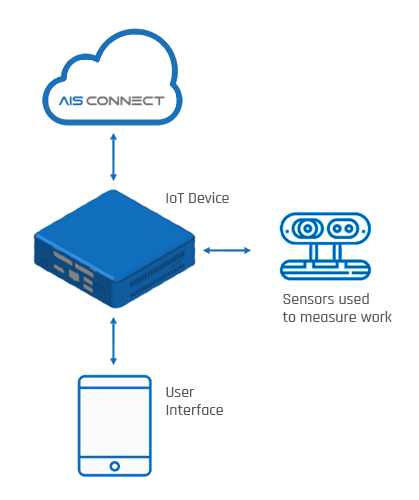

In the AIS Connect system, each machine or robot in a plant nursery is connected to the cloud through an AIS IoT Box. The IoT Box collects data from the sensors on the machines through a wide range of inputs such as USB, HDMI, Serial, Ethernet and GPIO. The IoT Box is also able to send commands to the machines. The collected data is processed in the IoT Box and uploaded to databases in the cloud platform of AIS Connect.

Users of AIS Connect have different access levels through web and mobile applications. This allows them to monitor the status of the machines and access the collected data. AIS Connect enables multiple players in a plant nursery to measure the performance of their workflow, analyse the collected data, plan for improvements, and act on those plans. In case the users face issues, they can ask for support from AIS and machine providers through AIS Connect.

Monitor and Manage

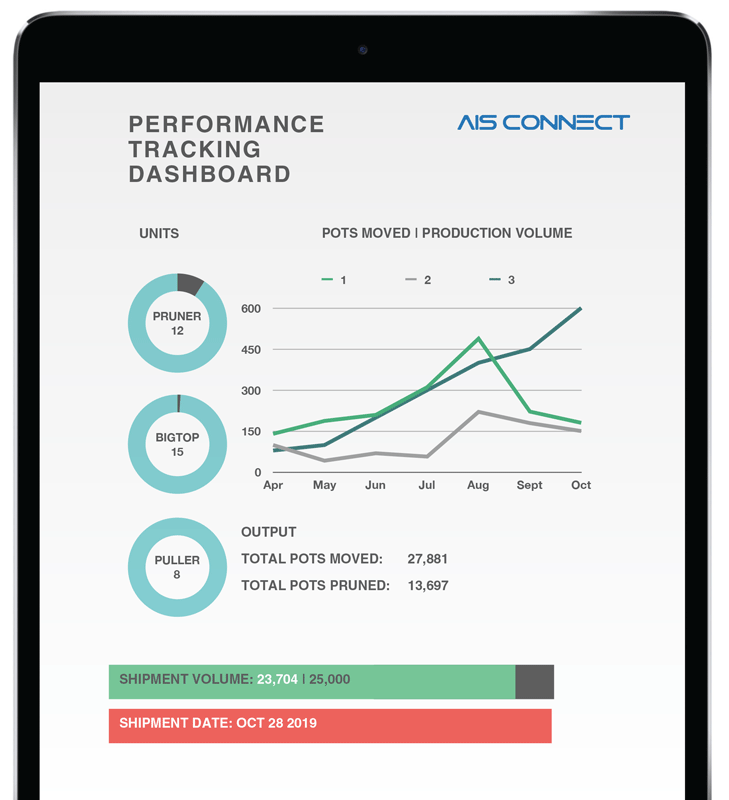

AIS Connect allows AIS and horticultural machine distributors to manage and monitor the machines in the field by tracking work volume and monitoring their health status. Collecting data allows machine manufacturers to perform predictive maintenance to increase reliability and lower repair costs. AIS and machine manufacturers can also issue and execute over the air (OTA) software updates through AIS Connect. In addition, AIS Connect enables machine manufacturers to issue invoices based on the work performed. The MaaS business model makes the machines affordable for the plant nurseries by lowering the initial cost extensively.

AIS Connect will bring a paradigm shift to the nature of the jobs performed by humans. By having a sensor-based cloud infrastructure to manage machines and autonomous robots, humans will not be lifting heavy objects or conducting repetitive, labor-intensive tasks. Humans will not be exposed to dangerous environments and micro-particles and hazardous gases at work. All those jobs will be done by autonomous robots and will be closely managed by AIS Connect. Many industries, such as food and horticulture, will be able to survive and thrive by reducing the cost of growing food and increase output using AIS Connect as an automation platform.