When people want to understand something, they compare their observations to an established standard. Standards give people structure around which they can thrive while aspiring toward even greater accomplishments and upgraded standards.

Productivity depends on standards, even as innovators seek to redefine them. Formalized standards are documents, both print and online, that include specifications, procedures and morphologies that detail assurances for the reliability of products and their composite materials. Standards represent the protocols that producers and consumers alike can trust as they strive to understand the world and its inherently competitive landscape.

Technology standardization

Through the centuries, technologies have gone through cycles of innovation, standardization and occasional ossification. Manufacturers are always seeking to improve productivity, and entrepreneurs will often distinguish themselves from competitors by adopting or developing innovations in technology.

The automobile industry exemplified the Second Industrial Revolution. Standards in manufacturing processes, parts specifications and related products, such as refined petroleum and roadways, paved the way toward expanded human progress. When consumers became confident they could top off their tank at any filling station and hire qualified mechanics wherever they happened to be, entire continents opened up for greater exploration.

Today’s businesses are increasingly digital. Characteristics of the Fourth Industrial Revolution entail a harmony of things physical and virtual, encouraging enterprises to pursue operational advantages that include:

-

Rapid prototyping of research and development (R&D) discoveries.

-

Process agility and ease of redesign.

-

Greater precision.

-

Transparency and accountability within supply chains.

-

Marketing flexibility.

-

Improved customer satisfaction and personalization.

Standards provide a kind of travel guide for modern innovation, navigating for entrepreneurs as they explore their immediate surroundings and peer over the horizon with eternal curiosity. Among emerging industries, the evident trailblazer is robotics, and standards that evolve alongside its myriad discoveries are mapping out new territory to make bleeding-edge research more practical and accessible to tentative consumers.

Standards and modular robotics

Robotics is intriguing because its products mimic the very human actions that led to the development of robotics. There are robots whose entire purpose is to manufacture goods that we once labored to produce ourselves and to perform chores that took so much valuable time away from us. Robots are even creating other robots, with potential impacts on economies and culture being debated among those whose lives have already adapted to the point that they can afford to engage in more inward-looking pursuits of philosophy and debate.

As we push ourselves to refine the form and function of robotics, we are moving beyond ancient fantasies of perfectible humanity to become caretakers of artificial agents that we hope will refine us in turn. To keep the madness out of the AI scientist, though, standards are essential for helping us plot a course through successive versions of hardware, software and intermediary operating systems that will define our relationship with smart machines.

Formal standards in robotics pertain to manufacturing process guidelines and consumer safety assurances. Organizations and federations have risen to address the rapid pace of innovation for both industrial robots and consumer robots. And entire communities have formed around the mutual interests of motivated members.

In parallel with formalized standards, some informal standards have grown out of innovation itself. For decades, researchers anticipated a robotic transformation from simple programs manipulating electronic appendages into autonomous agents of decision trees and mobility, but only in recent years have developments in homogeneous and heterogeneous robotics turned academic suppositions into practical solutions.

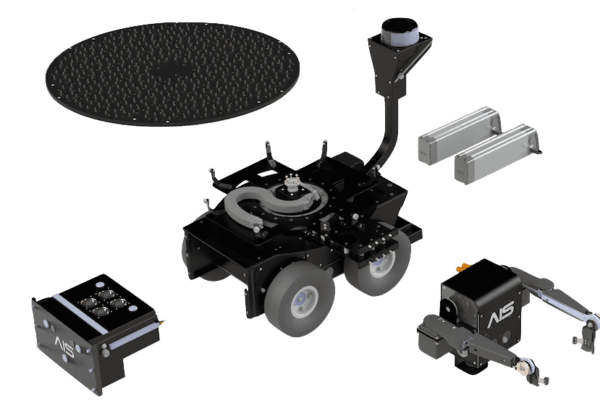

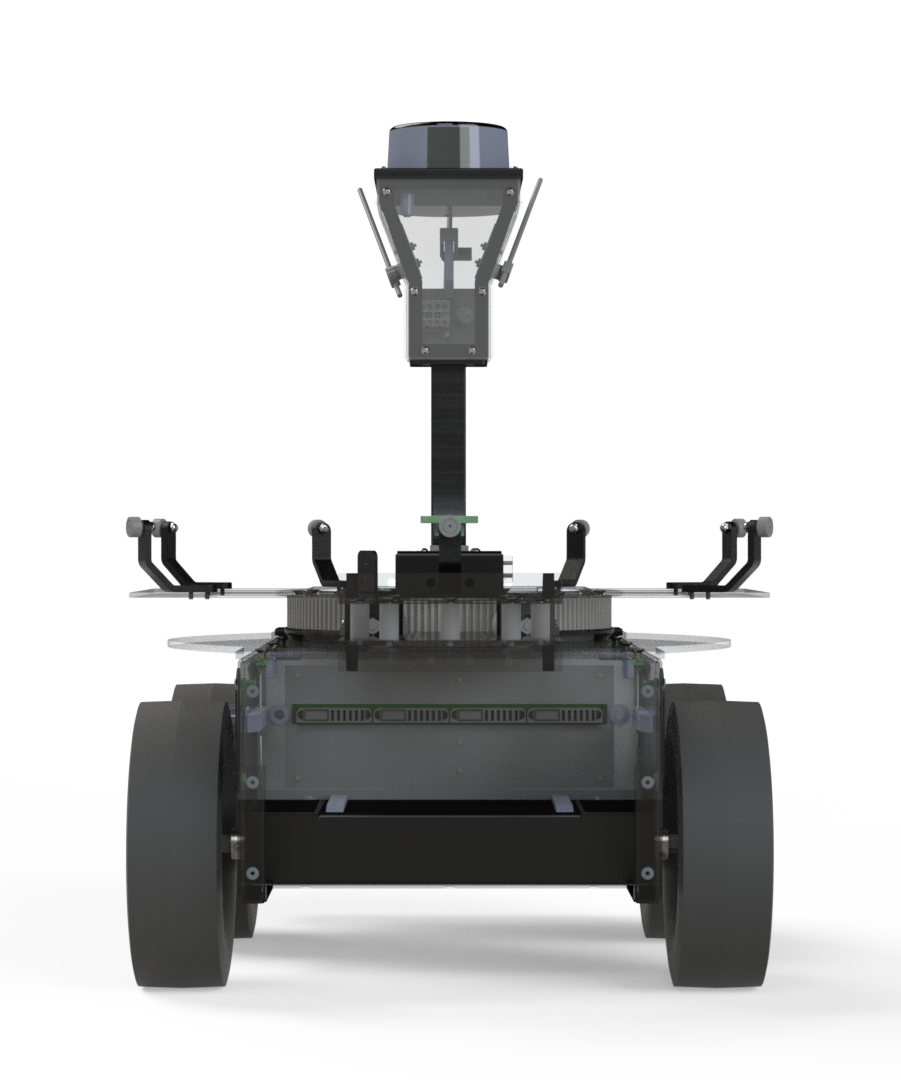

Foremost among this transformation toward robotic autonomy is the recent emergence of modular robots. As within the automobile industry, the design and manufacturing of practical modular robots are consolidating into standardized processes that promise reduced costs and enhanced consumer satisfaction. By the middle of this century, mobile robotic devices will be exploring continents as humans did during the previous century. Affordable robot components will be more interchangeable than ever, and owners will trick out their autonomous rides like they’re the roadsters of bygone days.

Advancements in component modularity and associated robotics interoperability are also helping to minimize difficulties with sustained innovation, thereby lowering barriers of entry into the marketplace and encouraging healthy competition to benefit consumers. Global trade will receive a boost from an expansion of automation, ranging from factory lines to distribution and delivery mechanisms.